In addition to inducing a warm feeling of wood, the wood facade provides the basis for the realization of the concept of sustainable development and design. The wood facade (wood facade), which is inspired by the natural environment, is very effective in meeting the mental and physical needs of the residents (which is one of the principles of sustainable architecture).

The desire to use wood material in construction (interior and facade) has always been of interest. Wood facade has been important for designers and architects for various reasons such as naturalness, beauty of wood facade, etc. According to the technology used in HPL panels, today it is possible to use wood as a facade (wood) of the building in various climates.

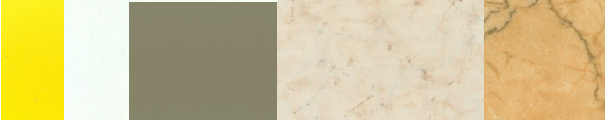

As mentioned before, due to the visual beauty of the wood facade, the use of wood in the facade of the building, either pure or combined with ceramics or stone or…, especially cream travertine stone, is very common.

– Why HPL facade (wood)?

HPL panels have different layers, one layer of which is made of natural wood, HPL panels can cover a larger surface area with wood than Thermowood and other materials. It has a wooden facade.

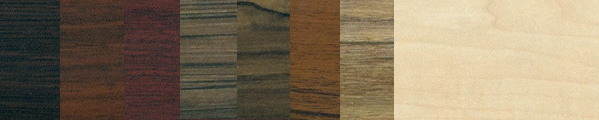

Due to having a wide range of color and texture, especially wood texture, HPL sheets provide the designer with very suitable conditions for facade design.

HPL sheets used in wood facades do not require paint (after the passage of time) and maintenance, unlike other wood facade materials that after 1 or 2 years They change color and need to be repainted.

The mechanical resistance of HPL sheets used in wood facades or other designs is not as high as in any of the alternative products such as composite, thermo wood, and ceramic facades.

Only HPL has a protective layer before installation on the facade (wood or…).

HPL sheets used in wood facades include fire classification B-S1D0/EGF and EN 13501-1, they are fire resistant, non-flammable, and slow burning. and it does not melt and does not explode, but Thermo Wood facade wood is not so resistant to fire, Thermo Woods are in class D in terms of fire resistance.

HPL sheets, unlike other wood facades, do not change color and shape against the UV rays of the sun, if the wood facade of Thermowood is left without any coating, it will turn gray in a short time. (due to ultraviolet rays).

· The HPL panel used in the wood facade has more resistance to moisture than the Thermowood wood facade.

Due to the characteristics of the HPL panel, it is possible to use it in the open air, wet environments such as swimming pools, the wooden facade of the building and in the construction and production of outdoor furniture.

Installing the HPL sheet is easy and fast, wood facade or HPL facade with different designs and colors does not change color against atmospheric factors such as sunlight, their weight is very They are light and easy to wash. Considering these advantages and many other cases, it can be said that HPL sheets with wood coating or various other coatings are a suitable option for facade design (wood).

The HPL facade is installed with a dry facade system, which is dry and without mortar, and is known as a rainproof wall.

– What is a dry view?

It is called a view that does not use cement mortar in its installation.

– Dry facade system components:

Dry facade (wood) systems include the following components:

Thermal insulation:

Thermal insulation is fixed to the substructure by mechanical connection or glue.

Support frame:

This frame can be made of aluminum, steel or saturated wood. Distances, sizes and types of connections are designed in such a way that they are resistant to destructive factors.

· Empty ventilation space:

In dry facade (wood) systems, they create an empty space between the facade (wood) and insulation to prevent moisture from entering the building.

Dry facade (wood) and connections:

Among the materials that can be used in dry (wood) facades are saturated resin panels or HPL panels, which have a wide range of colors and textures, even the texture of wood. Dry facade (wood) can be implemented with free joints.

– The steps of implementing a dry facade (wood) system:

· A box with dimensions suitable for the dry (wood) facade used, which is installed along each other on the wall of the building.

Installing the insulation board on the wall of the building.

· Vertical carrier profiles that are connected to the can using nails or rivets.

The dry facade (wood) used is connected to the body of the building according to the type of connection.

Due to the lack of mortar, the implementation of the dry facade system is much faster and easier than other facades in the high parts of the building, and in this system, there is periodic maintenance, especially in high buildings.